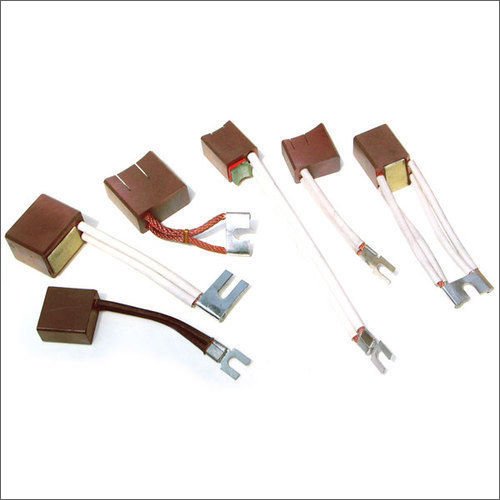

Carbon Brush For 400 KW DC Motor

Carbon Brush For 400 KW DC Motor Specification

- Brush Shape

- Rectangular block

- Bristle Color

- Dark grey

- Diameter

- Custom as per motor

- Other Material

- Copper powder, Graphite

- Function

- Conducts electrical current between stationary and rotating parts

- Use

- For electrical contact in DC Motor

- OEM Compatibility

- Available for various OEM DC motor models

- Electrical Resistivity

- Low resistivity (2070 m, typical for carbon brushes)

- Dimensions

- Standard and custom sizes available

- Working Life

- Long operational life under specified conditions

- Application Area

- Industrial, traction, and heavy-duty DC machines

- Mounting

- Clamp or stud-mounted

- Flexibility

- High wear resistance, self-lubricating

- Power Rating Compatibility

- 400 KW DC Motor

- Packaging

- Box or customized packaging as per order requirement

- Temperature Resistance

- Up to 200C

Carbon Brush For 400 KW DC Motor Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100000 Pieces Per Day

- Delivery Time

- 1-30 Days

About Carbon Brush For 400 KW DC Motor

Outstanding Features & Versatile Applications

The Carbon Brush for 400 KW DC Motor is engineered for triumphant usage in industrial, traction, and heavy-duty DC machines. Special features include high wear resistance, self-lubrication, and exceptional temperature endurance up to 200C. Its low electrical resistivity ensures efficient current transfer. Available in rectangular block shapes and custom diameters, it offers extra flexibility with both clamp or stud mounting options-delivering top-rated performance for various OEM and custom DC motor requirements.

Flexible Payment Terms and Handover Process

Valuation of each Carbon Brush for 400 KW DC Motor is transparent, ensuring value-driven transactions. We typically operate on FOB Indian ports, guaranteeing secure and timely shipment. Our sample policy is customer-focused; samples can be prepared upon request, with terms agreed prior to handover. All orders are packaged in either standard boxes or customized solutions, as per client requirements, making the handover and shipment procedures seamless and predictable for valued clients.

FAQ's of Carbon Brush For 400 KW DC Motor:

Q: How does the Carbon Brush for 400 KW DC Motor improve motor performance?

A: The brush's low electrical resistivity and high wear resistance enable strong electrical contact, minimizing downtime and enhancing the efficiency of DC motors in demanding industrial applications.Q: What materials are used in the manufacturing of this carbon brush?

A: This product is made from a precise composition of carbon, copper powder, and graphite, ensuring optimal conductivity, durability, and performance for heavy-duty usage.Q: When should I replace the carbon brush in my DC motor?

A: It is recommended to replace the carbon brush once noticeable wear, reduced performance, or sparking occurs. Regular inspection based on your application's operational hours ensures maximum equipment safety and efficiency.Q: Where can these carbon brushes be installed?

A: These brushes are suitable for a range of 400 KW DC Motors, especially in industrial, traction, and various heavy-duty DC machines, with compatibility for both OEM and custom models.Q: What is the process for ordering customized sizes?

A: You can request custom dimensions or shapes when placing your order. Our team will collaborate with you to determine the ideal specifications, ensuring the product fits your DC motor requirements precisely.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Brush Category

Slip Ring Carbon Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Brush Shape : Other, Rectangular

Diameter : 25 mm

Bristle Color : Black

Other Material : Other, Copper, Graphite

Vacuum Motor Carbon Brush

Minimum Order Quantity : 2 Pieces

Brush Shape : Other, Rectangular

Diameter : 12 mm

Bristle Color : Black

Other Material : Other, Copper Terminal

DC Motor Carbon Brush

Minimum Order Quantity : 2 Pieces

Brush Shape : Other, Rectangular

Diameter : 12 mm

Bristle Color : Gray

Other Material : Other, Copper, Graphite

Automotive Carbon Brush

Minimum Order Quantity : 2 Pieces

Brush Shape : Other, Rectangular

Diameter : Custom as per Application

Bristle Color : Dark Grey

Other Material : Other, Copper, Graphite Blend

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free