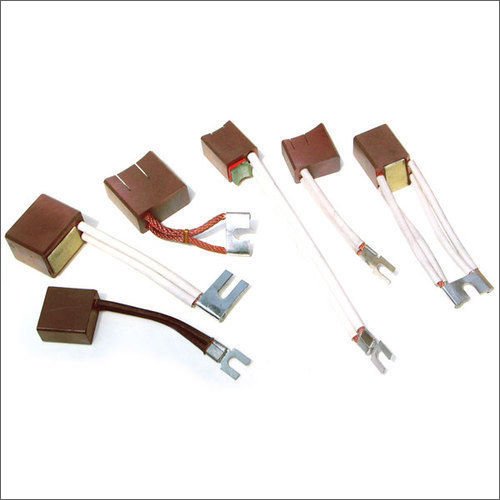

Industrial Carbon Brush

Industrial Carbon Brush Specification

- Diameter

- Varies as per requirement

- Bristle Color

- Dark Grey

- Function

- Conducts electrical current between stationary wires and rotating parts

- Handle Length

- NA (comes with fitted shunt or holder if required)

- Use

- Industrial Electrical Machines

- Other Material

- Copper, Graphite

- Brush Shape

- Rectangular / Square

- Packaging Type

- Box / Carton

- Hardness

- 60120 HB

- Mounting Type

- Pressed or bolted

- Self Lubrication

- Yes

- Application

- Motors, Generators, Alternators, Slip Rings, Welding Machines

- Features

- High conductivity, wear resistance, low friction loss, long service life

- Electrical Resistivity

- 813 m

- Weight

- As per size and model

- Compressive Strength

- 45 MPa

- Working Temperature

- Up to 180C

- Product Type

- Industrial Carbon Brush

- Grade

- EG/G/CG/SG (Customized)

- Operating Voltage

- Up to 600V

Industrial Carbon Brush Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100000 Pieces Per Day

- Delivery Time

- 1-30 Days

About Industrial Carbon Brush

Usage Method and Application Surfaces

Industrial Carbon Brushes excel in diverse application methods, typically installed by pressing or bolting onto the surfaces of motors, generators, alternators, and welding machines. Suitable for demanding continuous industrial usage, these brushes are precisely crafted for both rectangular and square shapes to synchronize with various contact surfaces. Whether replacing worn-out units or fitting into new assemblies, they seamlessly conduct electrical current, ensuring optimal contact and minimal surface wear for a range of heavy-duty applications.

Quick Delivery, Packaging Solutions, and Export Markets

Benefit from our express shipping options and enjoy the sale price, making your outlay cost-effective. Each Industrial Carbon Brush is securely packed in durable boxes or cartons, ensuring product integrity upon arrival. As a leading exporter, our main markets include Asia, Europe, Africa, and the Middle East, supported by trusted manufacturer and supplier channels in India. Experience prompt delivery times and attractive packaging that match the quality and performance of our esteemed products.

FAQ's of Industrial Carbon Brush:

Q: How are Industrial Carbon Brushes installed for motors and generators?

A: Industrial Carbon Brushes are mounted either by pressing or bolting, depending on the specific equirements of the equipment. They are designed for easy installation and alignment with stationary and rotating parts to ensure seamless electrical conduction.Q: What are the main benefits of using self-lubricating carbon brushes in industrial machines?

A: Self-lubricating carbon brushes minimize friction loss, enhance wear resistance, and provide longer service life. This results in reduced maintenance, improved efficiency, and reliable operation in heavy-duty electrical machines.Q: Where is the surface of application for these carbon brushes?

A: These brushes are applied on rotating parts such as the commutator or slip rings of motors, alternators, and welding machines. Their rectangular or square design provides optimal contact with these surfaces, reducing arcing and wear.Q: When should carbon brushes be replaced in industrial applications?

A: Carbon brushes should be replaced when their length falls below the manufacturer's recommended minimum or if noticeable wear, sparking, or irregular current conduction occurs during operation.Q: What packaging types are available for Industrial Carbon Brushes during delivery?

A: Our carbon brushes are carefully packed in robust boxes or cartons. This secure packaging ensures safe transit and product integrity, whether delivered locally or via international export channels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Brush Category

Carbon Brush For Motors And Generators

Price 3000 INR / Piece

Minimum Order Quantity : 2 Pieces

Other Material : Other, Carbon

Brush Shape : Other, Rectangular

Function : Current conduction and transfer

Use : Motors and Generators

Slip Ring Carbon Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Other Material : Other, Copper, Graphite

Brush Shape : Other, Rectangular

Function : Transmit Electrical Current Between Stationary and Rotating Parts

Use : For Electrical Slip Ring Applications

Alternator Copper Carbon Brush

Minimum Order Quantity : 2 Pieces

Other Material : Other, Copper and Carbon Composite

Brush Shape : Other, Rectangular

Function : Conducts Electrical Current between Stationary and Rotating Parts

Use : Alternator Electrical Contact

Electrographite Carbon Brush

Minimum Order Quantity : 2 Pieces

Other Material : Other, Electrographite

Brush Shape : Other, Rectangular / Customized

Function : Conducts current between stationary wires and rotating parts

Use : Industrial electrical applications

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free