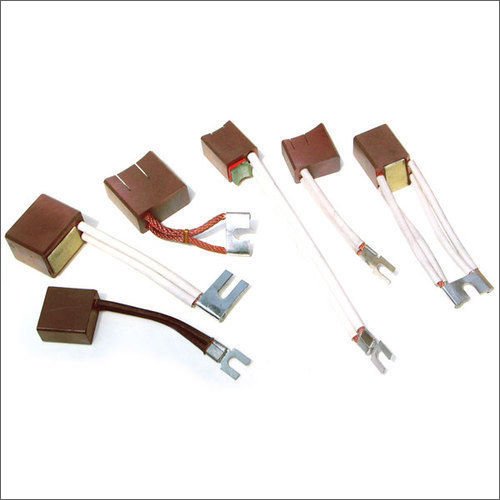

Industrial Carbon Brush Split Type With Flat Insulation Pad

Price 20 - 40000 INR/ Piece

Industrial Carbon Brush Split Type With Flat Insulation Pad Specification

- Function

- Conducts electric current between stationary wires and rotating parts

- Bristle Color

- Dark Grey

- Use

- Industrial electrical motors and generators

- Diameter

- Customizable (typically 8mm - 50mm)

- Other Material

- Carbon, Copper powder, Resin compound

- Brush Shape

- Split type rectangular/block with flat insulation pad

- Applications

- Slip rings, commutators, alternators, DC and AC motors

- Package Includes

- Carbon brush with flat insulation pad, mounting hardware (if specified)

- Insulation Pad Material

- High-grade pressed resin or phenolic laminate

- Working Temperature

- Up to 180°C

- Resistance

- Low electrical resistivity

- Contact Surface Finish

- Machined for optimal contact

- Current Rating

- Up to 250A (depending on size and material composition)

- Wear Resistance

- High durability against friction

- Mounting Type

- Split type with flat insulation pad for easy installation

Industrial Carbon Brush Split Type With Flat Insulation Pad Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100000 Pieces Per Day

- Delivery Time

- 1-30 Days

About Industrial Carbon Brush Split Type With Flat Insulation Pad

Industrial Carbon Brush Split Type with Flat Insulation Pad is very easy to install as well as simple to operate. One particular kind of carbon brush used in industrial settings, such as electric motors and generators, is this brush with a flat insulation pad. A flat insulation pad is sandwiched between the two halves of a split brush in this design. Industrial Carbon Brush Split Type with Flat Insulation Pad has high electrical conductivity, low friction, and low wear levels, making them long-lasting and durable. In high-voltage or high-current applications, where the brushes are put through a lot of wear and tear, it is frequently used.

Reliable Electrical Contact for Industrial Machinery

Our carbon brush split type with a flat insulation pad provides consistent, low-resistance electrical contact in motors, generators, and alternators. Its machined surface ensures optimal conduction while high-grade materials such as carbon and copper powder deliver outstanding durability. Designed for use in heavy-duty slip rings and commutators, it's an essential component for industrial applications.

Engineered for Durability and Safety

With high wear resistance and a working temperature tolerance of up to 180C, these brushes withstand demanding operational conditions. The insulation pad, made from pressed resin or phenolic laminate, prevents unintended electrical pathways and enhances equipment safety, supporting long service life and reliable performance.

FAQ's of Industrial Carbon Brush Split Type With Flat Insulation Pad:

Q: How is the industrial carbon brush split type with flat insulation pad installed?

A: The split type design with a flat insulation pad allows straightforward mounting onto slip rings or commutators. The brush is typically held in place with the provided mounting hardware, ensuring secure and efficient installation for industrial motors and generators.Q: What materials are used in the insulation pad, and why are they chosen?

A: The insulation pad is crafted from high-grade pressed resin or phenolic laminate. These materials offer excellent electrical insulation, heat resistance up to 180C, and mechanical strength, making them ideal for high-current, high-temperature industrial applications.Q: When should I consider replacing the carbon brushes in my equipment?

A: Replace the carbon brushes when you notice reduced performance, visible wear, or excessive sparking. Regular maintenance checks are recommended, especially in heavy-duty equipment, to maintain optimal current transfer and protect the machinery.Q: Where can the split type carbon brush with insulation pad be used?

A: This carbon brush is suitable for use in slip rings, commutators, alternators, and both DC and AC electrical motors found in industrial settings, power plants, manufacturing lines, and other heavy electrical equipment.Q: What is the manufacturing process for this type of carbon brush?

A: The process involves blending carbon, copper powder, and resin compounds to form the brush block, which is then machined for precise contact surfaces. The insulation pad is integrally molded or attached, and the entire assembly is finished according to industrial standards.Q: How does using a flat insulation pad benefit industrial equipment?

A: The flat insulation pad provides firm electrical isolation and mechanical stability, reducing the risk of accidental short circuits. It also ensures reliable current transfer and extends the service life of both the brush and the machinery.Q: What are the main advantages of choosing this product for industrial applications?

A: It delivers excellent electrical conductivity, high durability against wear and friction, straightforward installation, and reliable operation under high-stress conditions, making it a preferred choice for exporters, manufacturers, and suppliers in India and globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Brush Category

Carbon Brush For Motors And Generators

Price 3000 INR / Piece

Minimum Order Quantity : 2 Pieces

Other Material : Other, Carbon

Brush Shape : Other, Rectangular

Function : Current conduction and transfer

Bristle Color : Black

Home Appliances Carbon Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Other Material : Other, Copper, Plastic

Brush Shape : Other, Rectangular

Function : Conducts Electrical Current

Bristle Color : Black

Slip Ring Carbon Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Other Material : Other, Copper, Graphite

Brush Shape : Other, Rectangular

Function : Transmit Electrical Current Between Stationary and Rotating Parts

Bristle Color : Black

DC Motor Carbon Brush

Minimum Order Quantity : 2 Pieces

Other Material : Other, Copper, Graphite

Brush Shape : Other, Rectangular

Function : Conduct electrical current between stationary wires and moving parts

Bristle Color : Gray

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS