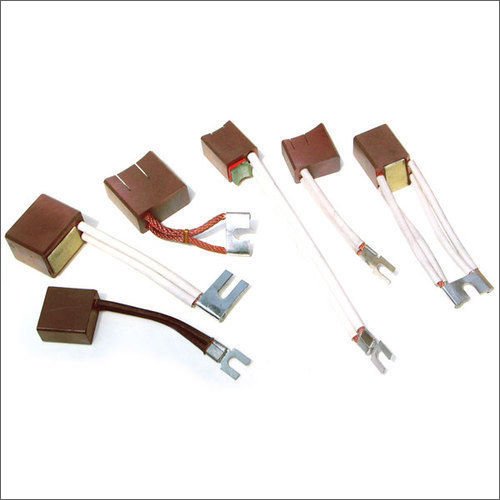

Marble Cutter Carbon Brush

Price 20 - 40000 INR/ Piece

Marble Cutter Carbon Brush Specification

- Brush Shape

- Rectangular

- Other Material

- Copper Wire, Plastic

- Function

- Conducts Electric Current in Power Tools

- Use

- Marble Cutter Machine

- Bristle Color

- Black

- Diameter

- Standard (Varies by Model)

- Pack Contains

- 2 Pieces

- Electrical Conductivity

- High

- Mounting Type

- Spring Loaded

- Weight

- Approx. 10 grams (Pair)

- Lifespan

- Long-Lasting Under Normal Use

- Resistant to Wear

- Yes

- Material

- Carbon

- Model Compatibility

- Universal (Varies as per Cutter Model)

- Application

- Replacement Part for Marble Cutter

- Operating Temperature

- -20°C to 80°C

Marble Cutter Carbon Brush Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100000 Pieces Per Day

- Delivery Time

- 1-30 Days

About Marble Cutter Carbon Brush

Usage & Applications: Superior Conductivity and Longevity

Our Marble Cutter Carbon Brush is engineered for reliable use in marble cutter machines, making it a select choice for professionals and contractors alike. The brush's superior conductivity and robust materials ensure consistent power transfer, reducing downtime due to worn-out components. Designed for universal compatibility and precision mounting, it is an indispensable replacement part in both renovation projects and new installations. Benefit from its long-lasting durability and resistant characteristics for optimal machine performance.

FOB Port & Supply Capabilities: Seamless Delivery Nationwide

Our FOB shipping port conveniently connects with key destinations, ensuring expedited freight and secure packaging. With a substantial supply ability, we efficiently meet bulk proposal amounts from buyers across India's main domestic market. Each carbon brush pair is meticulously packed for safe transit. Our established logistics network guarantees timely deliveries, giving customers peace of mind and cost-effective procurement whether for single units or repeat orders.

FAQ's of Marble Cutter Carbon Brush:

Q: How does the Marble Cutter Carbon Brush enhance machine performance?

A: The Marble Cutter Carbon Brush ensures superior electrical conductivity, resulting in smoother power transfer and reduced sparking. This prolongs machine lifespan and boosts cutting efficiency.Q: What is the process for replacing the carbon brush in a marble cutter?

A: To replace the carbon brush, turn off the power tool and detach its housing. Remove the old brush, insert the new spring-loaded carbon brush, secure it, and reassemble the cutter before testing.Q: When should I replace the carbon brush in my marble cutter?

A: You should replace the carbon brush when you notice decreased performance, visible wear, or excessive sparking in your marble cutter. Regular maintenance extends the tool's lifespan.Q: Where is your main supply market for Marble Cutter Carbon Brush?

A: We predominantly supply the Marble Cutter Carbon Brush to India's main domestic market, catering to manufacturers, suppliers, and end-users nationwide.Q: What are the material features that make this brush long-lasting?

A: The brush is made from select carbon and copper wire, providing high electrical conductivity and strong wear resistance. Its pristine rectangular design ensures optimal contact and durability under normal operating conditions.Q: How does the packaging contribute to product quality during delivery?

A: Each carbon brush pair is securely packaged to prevent damage during freight, ensuring that customers receive pristine, ready-to-use replacement parts consistently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Brush Category

Carbon Brush For Motors And Generators

Price 3000 INR / Piece

Minimum Order Quantity : 2 Pieces

Diameter : 16 mm

Use : Motors and Generators

Bristle Color : Black

Brush Shape : Other, Rectangular

Industrial Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Diameter : Approx. 100 mm

Use : Industrial Cleaning and Surface Finishing

Bristle Color : Metallic / Yellow / Black

Brush Shape : Other, Circular/Wheel

Slip Ring Carbon Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Diameter : 25 mm

Use : For Electrical Slip Ring Applications

Bristle Color : Black

Brush Shape : Other, Rectangular

Industrial Carbon Brush With Single Plate

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Diameter : 20 mm

Use : Electrical machinery, industrial motors, generators

Bristle Color : Dark grey

Brush Shape : Other, Rectangular with single mounting plate

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free