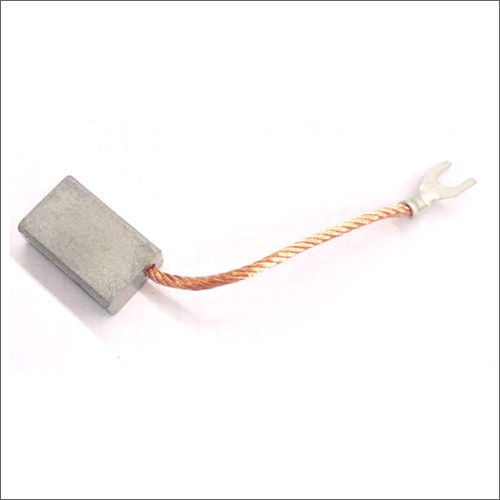

Industrial Electrographite Carbon Brush

Industrial Electrographite Carbon Brush Specification

- Brush Shape

- Rectangular or square block

- Other Material

- Electrographite

- Diameter

- Depends on brush size, typically 10 mm to 100 mm

- Use

- Industrial Electrical Equipment

- Function

- Transfer electrical current between stationary and rotating parts

- Bristle Color

- Dark grey to black

- Handle Length

- Customizable per application requirements

- Material Purity

- High purity graphite

- Grade

- EG (Electrographite Grade)

- Surface Finish

- Fine machined

- Operating Temperature Range

- -40C to 300C

- Lubrication

- Self-lubricating properties

- Moisture Resistance

- High

- Density

- 1.70-1.85 g/cm

- Hardness

- 60-85 Shore

- Mounting Type

- Spring loaded or bolted

- Electrical Resistivity

- Low, typically 5-12 m

- Service Life

- Long lifespan with minimal wear

- Current Density

- Up to 10 A/cm

- Application

- Slip rings, commutators, electric motors, generators

Industrial Electrographite Carbon Brush Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100000 Pieces Per Day

- Delivery Time

- 1-30 Days

About Industrial Electrographite Carbon Brush

Industrial Electrographite Carbon Brush is created by compressing and baking a mixture of graphite and carbon particles at a high temperature and pressure to create a solid block. After that, the block is machined to the desired size and shape for the motor or generator. Electric motors and generators use a particular kind of brush is this brush. Apart from this, our provided Industrial Electrographite Carbon Brush is made for use in high-speed or high-temperature applications. Graphite is frequently combined with other substances, like copper or metal alloys, that are intended to offer good conductivity, low friction, and wear resistance.

Exceptional Performance and Longevity

Electrographite carbon brushes stand out due to their high purity and precise engineering, which deliver low electrical resistivity and outstanding wear resistance. This combination allows for efficient current transfer and extended service life in a diverse range of applications, including motors, generators, slip rings, and commutators. Their reliable operation translates into reduced maintenance and system downtime, making them highly valued in industrial environments.

Versatile Customization and High Compatibility

These carbon brushes are available in various shapes and sizes, such as rectangular or square blocks, with diameters ranging from 10 mm to 100 mm. Each brush can be customized for specific handle lengths and mounting types-either spring loaded or bolted. This ensures perfect compatibility with industrial electrical equipment, tailored to unique installation and operational demands.

Engineered for Demanding Conditions

Designed to perform under demanding conditions, these carbon brushes withstand temperatures between -40C and 300C, high current densities up to 10 A/cm2, and harsh moisture environments. Their self-lubricating and high-purity electrographite composition provides stable performance, prevents excessive wear, and extends overall equipment lifespan even in rigorous operating coalitions.

FAQ's of Industrial Electrographite Carbon Brush:

Q: How do electrographite carbon brushes enhance electrical equipment performance?

A: Electrographite carbon brushes offer low electrical resistivity and high purity, resulting in efficient current transfer with minimal wear. Their self-lubricating properties reduce friction, helping to prolong equipment lifespan and decrease maintenance frequency in electric motors and generators.Q: What applications are these EG-grade carbon brushes most suited for?

A: They are primarily used in industrial slip rings, commutators, electric motors, and generators-making them ideal for heavy-duty equipment that demands reliable current transfer between stationary and rotating components.Q: When should these brushes be replaced in industrial machinery?

A: Replacement timing depends on usage intensity and environmental conditions; however, their long service life and high wear resistance mean that they require changing less frequently than many alternatives. Regular inspections are recommended to monitor brush length and surface condition for optimal operation.Q: Where are these industrial electrographite carbon brushes manufactured and supplied from?

A: These brushes are engineered, produced, and exported from India, serving industries around the world with consistent quality and adherence to international performance standards.Q: What is the typical process for installing these carbon brushes?

A: Installation involves selecting the suitable brush according to size and equipment requirements, then mounting it using either spring-loaded or bolted mechanisms. Proper alignment and secure fitting are critical for efficient operation and minimizing electrical losses.Q: How does the design support usage in harsh environments?

A: The high moisture resistance, broad operating temperature range, and self-lubricating properties allow these brushes to function reliably in tough industrial conditions, reducing risk of premature failure or performance degradation.Q: What are the benefits of choosing EG-grade electrographite over other materials?

A: EG-grade electrographite offers exceptional conductivity, minimal wear, high purity, and resistance to moisture-all leading to improved equipment reliability, reduced maintenance, and greater operational efficiency in industrial electrical settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Brush Category

FHP Mixer Carbon Brush

Minimum Order Quantity : 2 Pieces

Function : Conducts electrical current between stationary wires and rotating motor parts

Bristle Color : Black

Use : Mixer, Grinder, Blender Motor Spares

Diameter : 6 mm

Silver Graphite Carbon Brush

Minimum Order Quantity : 2 Pieces

Function : Conducts Electric Current and Reduces Sparking

Bristle Color : Grey

Use : Electrical Equipment and Motors

Diameter : 18 mm

Industrial Carbon Brush Split Type With Flat Insulation Pad

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Function : Conducts electric current between stationary wires and rotating parts

Bristle Color : Dark Grey

Use : Industrial electrical motors and generators

Diameter : Customizable (typically 8mm 50mm)

Marble Cutter Carbon Brush

Price 20 - 40000 INR / Piece

Minimum Order Quantity : 2 Pieces

Function : Conducts Electric Current in Power Tools

Bristle Color : Black

Use : Marble Cutter Machine

Diameter : Standard (Varies by Model)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS